Email tɛ se ka kɛ lankolon ye

Password tɛ se ka kɛ lankolon ye

Email cogoya fili

Email tɛ se ka kɛ lankolon ye

Email bɛ yen kaban

6-20 sɛbɛnni(sɛbɛnniw fara jatedenw dɔrɔn kan)

Daɲɛ dogolen tɛ bɛn ɲɔgɔn ma

Email cogoya fili

Email tɛ se ka kɛ lankolon ye

Email tɛ yen

6-20 sɛbɛnni(sɛbɛnniw fara jatedenw dɔrɔn kan)

Daɲɛ dogolen tɛ bɛn ɲɔgɔn ma

Kunnafoniw

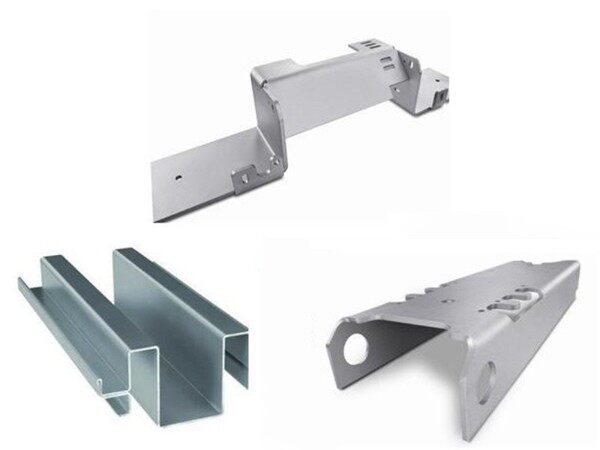

Sheet Metal Bending Process - 5 Common Processing Problems and Countermeasures

First, let's talk about the base wood principle of the sheet metal bending process.

As we all know - the sheet metal bending process refers to the processing of changing the angle of plates or plates. (for example, bend the plate into a V shape, U shape, etc.)

Take the bending deformation of V-shaped sheet metal bending parts as an example.

The processing process

- The punching movement contacts the sheet metal (blank) due to the different contact point forces of the punch and the concave die, resulting in a short bending moment. Under the action of the bending moment, elastic deformation occurs, resulting in bending;

- As the punch continues to descend, the blank and the surface of the die gradually come into contact, so that the bending radius and bending force arm are reduced, and the contact point between the blank and the die is moved from the two shoulders of the die to the two inclined planes of the die (at the beginning of plastic deformation);

- With the continuous downward movement of the punch, both ends of the blank contact the inclined surface of the punch and start bending (back bending stage);

- In the flattening stage, as the gap between the male and female dies becomes smaller, the sheet metal is flattened between the male and female dies;

5 problems encountered in sheet metal bending processing and countermeasures

First: causes of hole deformation caused by bending

When using elastic bending and positioning with holes, the outer side of the bending arm is pulled due to the friction between the die surface and the outer surface of the workpiece, which deforms the positioning hole.

Coping method: adopt shape bending. Increase the pressure of the ejector plate. A pitted lattice pattern is added to the ejector plate to increase the friction and prevent the workpiece from sliding when bending.

Second: the reason why the bending edge is not straight and the size is unstable

The design process does not arrange line pressing or pre-bending. Insufficient material pressing force. The round corners of the punch and die are worn asymmetrically or the bending force is uneven. The height dimension is too small.

Coping method: arrange the design of the pressing line or pre-bending process. Increase the pressing force. The clearance between punch and die is even and the fillet is polished. The height dimension cannot be less than the minimum limit dimension.

Third: reasons for cracks in bending angle

The inner radius of bending is too small. The material grain direction is parallel to the bending curve. The burr side of the blank is outward. Poor plasticity of metals.

Solution: increase the bending radius of the punch. Change blanking layout. The burr is changed in the fillet of the workpiece. Anneal or use soft materials.

Fourth: causes of external surface scratch after workpiece bending

The surface of raw materials is not smooth. The bending radius of the punch is too small. The bending clearance is too small.

Countermeasures: improve the smoothness of punch and die Increase the bending radius of punch. Adjust the bending clearance.

Fifth: reasons for thinning of extruded materials on curved surfaces

Die fillet is too small. The clearance between male and female dies is too small.

Countermeasures: increase the fillet radius of the die. Correct the clearance between punch and die.

Searching for a cnc cutting sheet metal, cnc sheet metal punching machine, cnc machine for sheet metal fabrication manufacturer from China, you can get high-quality products at a nice price.