Email tɛ se ka kɛ lankolon ye

Password tɛ se ka kɛ lankolon ye

Email cogoya fili

Email tɛ se ka kɛ lankolon ye

Email bɛ yen kaban

6-20 sɛbɛnni(sɛbɛnniw fara jatedenw dɔrɔn kan)

Daɲɛ dogolen tɛ bɛn ɲɔgɔn ma

Email cogoya fili

Email tɛ se ka kɛ lankolon ye

Email tɛ yen

6-20 sɛbɛnni(sɛbɛnniw fara jatedenw dɔrɔn kan)

Daɲɛ dogolen tɛ bɛn ɲɔgɔn ma

Kunnafoniw

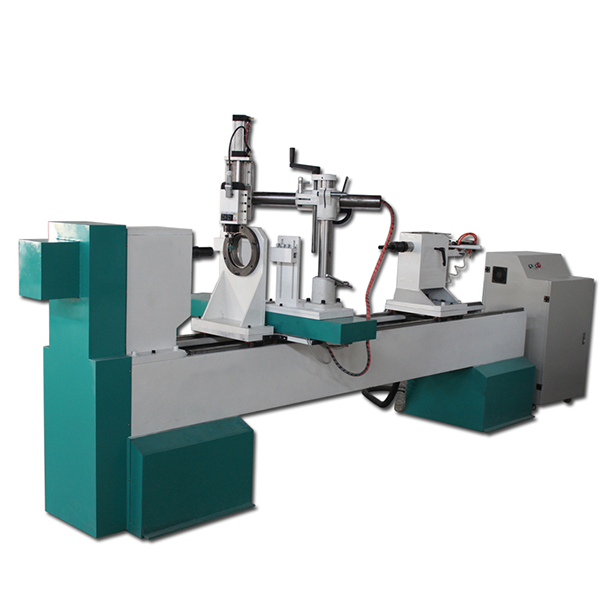

What is CNC Wood Lathe?(1)

With the wide application of science and technology in the wood processing industry, numerical control woodworking machinery has been popularized. The emergence of numerical control wood lathe is of epoch-making significance. It not only brings revolutionary changes to the traditional wood lathe but is also a symbol of the industrialization of the wood processing industry. With the continuous progress of numerical control technology, the application field of numerical control wood lathe is also expanding.

Definition of CNC wood lathe

CNC wood lathes are high-tech products integrating machinery, electricity, and pneumatics. It is suitable for workpieces with large diameters and a short length. It can process hardwood and cork stickers with high-speed steel or cemented carbide tools and can complete the rough and fine processing of circles, inner holes, end faces, cones, cutting, cutting, etc. It realizes full automation and completes products at one time, which greatly improves the efficiency of the CNC wood lathe. It is mainly used to process handicrafts such as columns, wooden bowls, pens, and other workpieces with rotating surfaces. It is a machine tool widely used in weapon manufacturing. Rotating machinery such as milling machines and drilling machines are extended from lathes.

CNC wood lathe is mainly used for processing various stair columns, roman columns, table and chair legs, basins, wooden vases, wooden column tables, sticks, wooden furniture, children's bed columns, etc. It can also process plate, goblet, bottle cap, cup cap, cup cap, handle, rolling pin, flute, flute, suona, Cello accessories, etc. It is especially suitable for large-scale production in small and medium-sized wood enterprises. It can flexibly set the shape at any time and quickly change the processing style. In traditional lathe processing, only one product can be processed at a time. CNC lathe has two axis, two axis, and three-axis CNC wood lathe, which can process 2 or 3 products at the same time, with the same size and size. The operation is simple, the drawing is convenient and easy to understand. The product style of one-click conversion has no professional knowledge personnel to carry out a little training. The fully automatic CNC wood lathe can operate 2-3 sets at the same time, which greatly improves the processing efficiency, saves labor, saves money, and brings good economic benefits.

CNC wood lathe category

CNC wood lathes are classified as follows:

- From the processing wood length and short line distribution: CNC wood lathe within 1 meter, CNC wood lathe within 1 meter, CNC wood lathe below 5 meters, CNC wood lathe within 2 meters; The effective processing of 1 meter CNC wood lathe is mainly used for solid wood table legs, chair legs, sofa feet, tea feet, and other furniture accessories. The CNC wood lathe processes one meter and five meters, which is mainly used for wood products such as wooden ladders, general columns, clothes hangers, bars, etc. The effective processing of a 2-meter CNC wood lathe is mainly used for the processing of long wood products, such as head columns, roman columns, etc.

- Distribution in terms of processing efficiency: one workpiece is processed at a time, and two parts are processed at the same time.

- In terms of processing technology, it is divided into an ordinary lathe, CNC lathe, and multi-function CNC wood lathe, which can be used for turning, grooving, twisting fried dough twists, and carving.