Email tɛ se ka kɛ lankolon ye

Password tɛ se ka kɛ lankolon ye

Email cogoya fili

Email tɛ se ka kɛ lankolon ye

Email bɛ yen kaban

6-20 sɛbɛnni(sɛbɛnniw fara jatedenw dɔrɔn kan)

Daɲɛ dogolen tɛ bɛn ɲɔgɔn ma

Email cogoya fili

Email tɛ se ka kɛ lankolon ye

Email tɛ yen

6-20 sɛbɛnni(sɛbɛnniw fara jatedenw dɔrɔn kan)

Daɲɛ dogolen tɛ bɛn ɲɔgɔn ma

Kunnafoniw

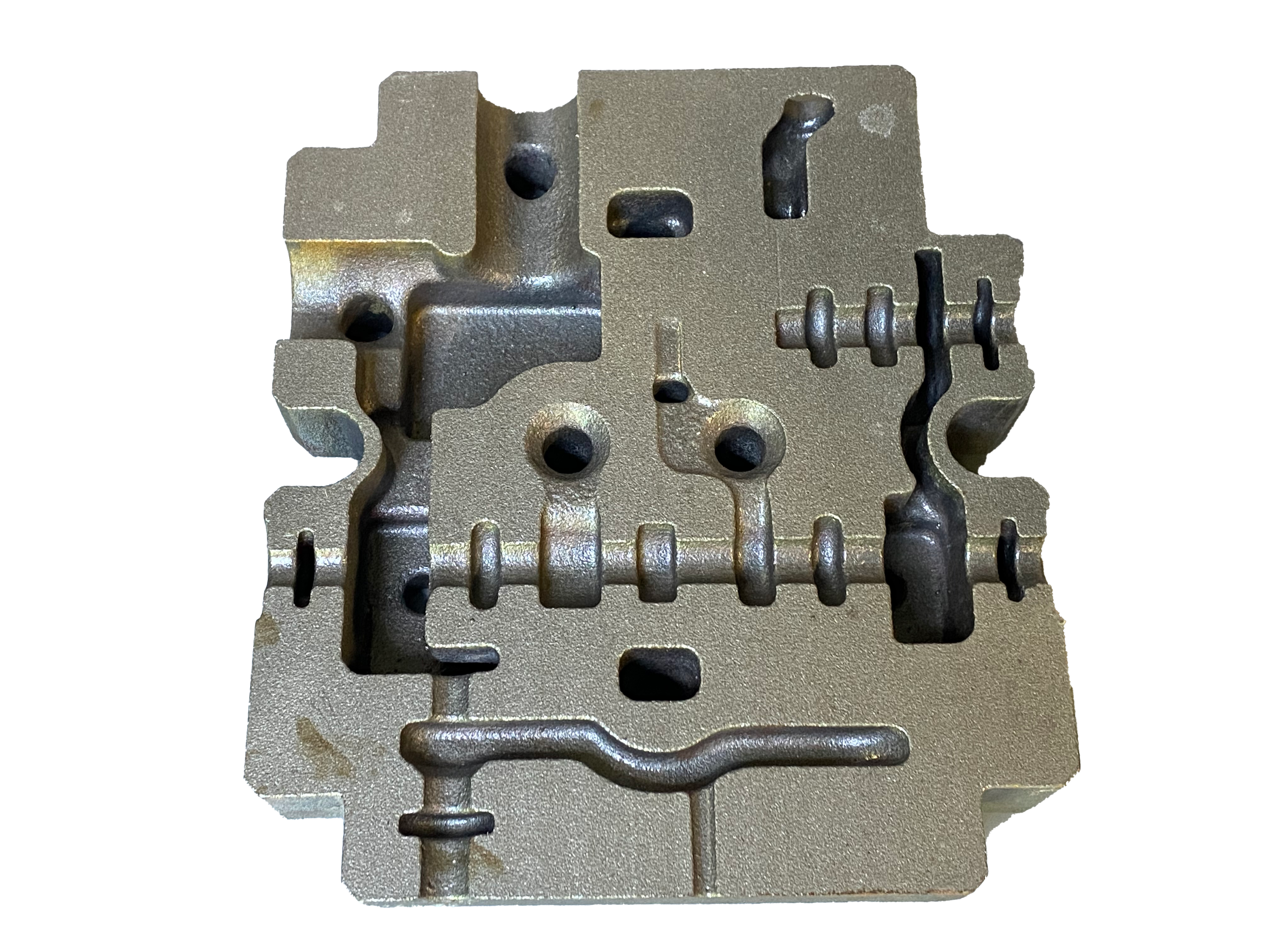

Something You should Know about Grey Cast Iron(1)

Mechanical properties of gray cast iron

Because graphite exists in common gray cast iron, and the tensile strength of graphite is almost zero, cast iron can be regarded as steel full of cracks or voids. Graphite not only destroys the continuity of the matrix but also reduces the effective cross-sectional area of the metal matrix to accept the load, which greatly increases the practical stress; At the same time, it is easy to form stress concentration at the sharp corners of graphite, so that the stress at the sharp corners is much greater than the uniform stress. The former is called the reduction of graphite, and the latter is called the cutting of graphite.

Therefore, the tensile strength and modulus of elasticity of gray cast iron are much lower than that of steel σ B is about 120 ~ 250Mpa, its compressive strength is close to that of steel, and it can reach 600 ~ 800MPa in general. Its plasticity and toughness are close to zero, belonging to brittleness data. The greater the number, size, and distribution of graphite flakes in gray cast iron, the greater the impact on the mechanical properties. However, the existence of graphite has little effect on the compressive strength of grey cast iron. Because the compressive strength mainly depends on the matrix structure of grey cast iron, the compressive strength of grey cast iron is similar to that of steel. When there is a sharp notch in the sample similar to the graphite flake in gray cast iron, the stress near the notch can reach more than 5 times the uniform value. The existence of this stress concentration phenomenon makes the practical stress of the matrix at the graphite edge exceed its yield strength even when the gray cast iron receives a relatively small load (far from reaching the yield strength of the matrix). Therefore, there will be residual deformation of the metal and even cracks (when the practical stress exceeds the strength limit of the matrix).

The appearance of the graphite edge crack further reduces the effective cross-sectional area of the gray cast iron receiving the load and intensifies the phenomenon of stress concentration. The top of the stress concentration also moves rapidly with the crack, making the crack expand quickly, and the brittle damage of the whole casting occurs. Therefore, due to the reduction and cutting effect of graphite, the strength of cast iron metal matrix can not be fully developed. According to statistics, the application rate of common gray cast iron matrix strength is generally not more than 30% ~ 50%, which shows that the tensile strength of gray cast iron is very low.

In addition, due to the serious stress concentration phenomenon caused by the presence of graphite, the early onset of cracks is formed, and the ability to resist crack development is poor, resulting in brittle fracture. Therefore, the plasticity and toughness of gray cast iron can hardly be shown. The performance degradation caused by the presence of flake graphite is not the algebraic sum of the two, and the cutting action often does more harm to the matrix than the reduction action.

Incidentally, when ordinary gray cast iron is under stress, a small amount of residual deformation is often caused due to the stress concentration at the graphite edge. Therefore, the stress-strain curve of gray cast iron is not linear even under the action of low stress but has a certain curvature. Therefore, the elastic modulus of gray cast iron is of relative significance.

Make a purchase of cast iron rooster, martin cast iron, windmill cast iron from China, you can get them at a good price if you have a large quantity. We hope to be your long-term partner.