Email tɛ se ka kɛ lankolon ye

Password tɛ se ka kɛ lankolon ye

Email cogoya fili

Email tɛ se ka kɛ lankolon ye

Email bɛ yen kaban

6-20 sɛbɛnni(sɛbɛnniw fara jatedenw dɔrɔn kan)

Daɲɛ dogolen tɛ bɛn ɲɔgɔn ma

Email cogoya fili

Email tɛ se ka kɛ lankolon ye

Email tɛ yen

6-20 sɛbɛnni(sɛbɛnniw fara jatedenw dɔrɔn kan)

Daɲɛ dogolen tɛ bɛn ɲɔgɔn ma

Kunnafoniw

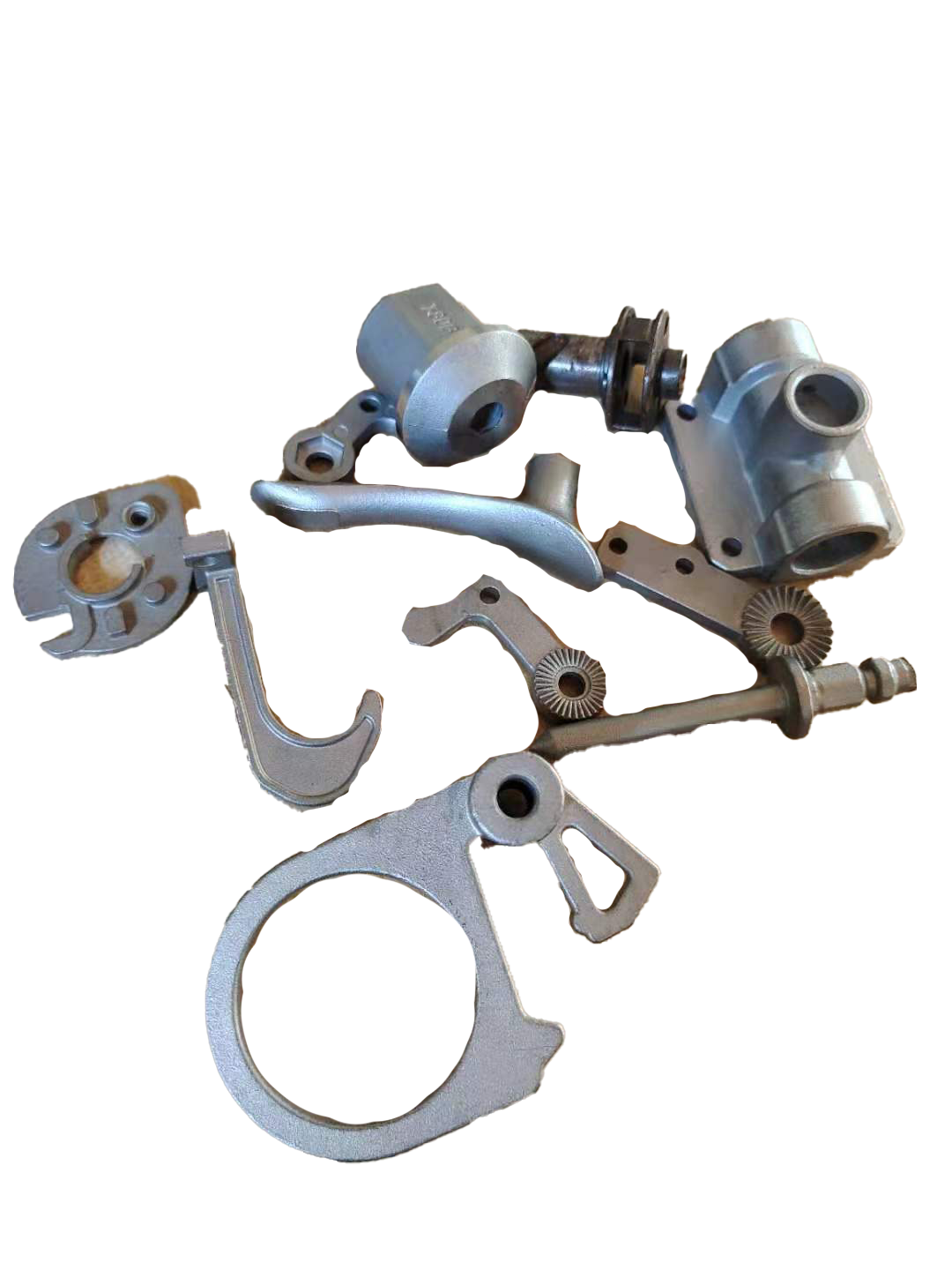

Six Common Casting Methods and Their Advantages and Disadvantages(2)

Die casting

The principle of the die casting process is to use high pressure to press the liquid metal into a precision metal mold cavity at high speed, and the liquid metal is cooled and solidified under pressure to form a casting. Cold and hot chamber die casting are two basic ways of the die casting process. In cold chamber die casting, the liquid metal is poured into the pressure chamber by a manual or automatic pouring device, and then the injection punch advances to hydraulically inject the metal into the mold cavity. In the hot chamber die casting process, the pressure chamber is perpendicular to the crucible, and the metal liquid automatically flows into the pressure chamber through the feed port on the pressure chamber. The injection punch moves downward to push the liquid metal into the cavity through the gooseneck. After the liquid metal solidifies, the die-casting die is opened and the casting is taken out to complete a die-casting cycle.

Advantage

The product quality is good. The dimensional accuracy of castings is high, which is generally equivalent to grade 6-7, or even grade 4; Good surface finish, generally equivalent to grade 5~8; The strength and hardness are higher, and the strength is generally 25~30% higher than that of sand casting, but the elongation is reduced by about 70%; Stable size and good interchangeability; Can die-cast thin-walled complex castings; High production efficiency. For example, the domestic J Ⅲ 3 horizontal cold air die casting machine can die-cast 600 ~ 700 times in eight hours on average, and the small hot chamber die casting machine can die-cast 3000 ~ 7000 times in eight hours on average; The service life of the die-casting mold is long. A pair of die-casting mold and die-casting clock alloy can have a service life of hundreds of thousands or even millions of times; Easy to realize mechanization and automation; The economic effect is excellent. Because the size of die-casting parts is accurate, the surface is bright and clean. Generally, it is no longer used directly for machining, or the processing volume is very small, so it not only improves the utilization rate of metal but also reduces a lot of processing equipment and working hours; The casting price is easy; Combined die casting can be used with other metallic or non-metallic materials. It saves both assembly time and metal.

Disadvantages and limitations

During die casting, due to the high speed of filling the cavity with liquid metal and the unstable flow state, the general die casting method is adopted, so the castings are prone to produce pores and cannot be heat treated; For castings with complex concave, die casting is difficult; High melting point alloys (such as copper, ferrous metals), die-casting mold life is low; It is not suitable for small batch production. The main reason is that the manufacturing cost of the die-casting mold is high, the production efficiency of the die-casting machine is high, and small batch production is uneconomical.

Metal mold casting

Also known as hard mold casting, it is a casting method in which liquid metal is poured into the metal mold to obtain castings. The mold is made of metal and can be used repeatedly (hundreds to thousands of times), also known as permanent mold casting. Generally, the metal mold is made of cast iron and cast steel. The inner cavity of the casting can be either a metal core or a sand core. There are many kinds of structures of metal type, such as horizontal type, heavy direct type, and composite type. Among them, vertical parting is convenient for opening the inner gate and taking out castings; Horizontal parting is often used to produce thin-walled Wheel Castings; The upper half of the compound parting is formed by the hinge connection of the two halves of the vertical parting, and the lower half is a fixed horizontal bottom plate, which is mainly used for the casting of more complex castings.

Advantage

It has good reusability and can be "cast in one type and many times", which saves modeling materials and modeling hours. Due to the strong cooling ability of the metal mold to the casting, the structure of the casting is dense and the mechanical properties are high. The dimensional accuracy of castings is high, and the tolerance grade is it12 ~ IT14; The surface roughness is low, and RA is 6.3m. No sand or less sand is used in metal mold casting, which improves the working conditions.

Disadvantages and limitations

The manufacturing cost of metal mold is high, the cycle is long, and the process requirements are strict. It is not suitable for the production of a single piece and small batch castings. It is mainly suitable for the mass production of non-ferrous alloy castings, such as aluminum pistons, cylinder blocks, cylinder heads, oil pump shells, and copper alloy bearing shells and sleeves for aircraft, automobiles, internal combustion engines, motorcycles, etc. For ferrous alloy castings, it is also limited to medium and small castings with simple shapes.

Searching for a carving wax for lost wax casting, precision lost wax casting, lost wax casting gold manufacturer from China, you can get high-quality products at a nice price.