Email tɛ se ka kɛ lankolon ye

Password tɛ se ka kɛ lankolon ye

Email cogoya fili

Email tɛ se ka kɛ lankolon ye

Email bɛ yen kaban

6-20 sɛbɛnni(sɛbɛnniw fara jatedenw dɔrɔn kan)

Daɲɛ dogolen tɛ bɛn ɲɔgɔn ma

Email cogoya fili

Email tɛ se ka kɛ lankolon ye

Email tɛ yen

6-20 sɛbɛnni(sɛbɛnniw fara jatedenw dɔrɔn kan)

Daɲɛ dogolen tɛ bɛn ɲɔgɔn ma

Kunnafoniw

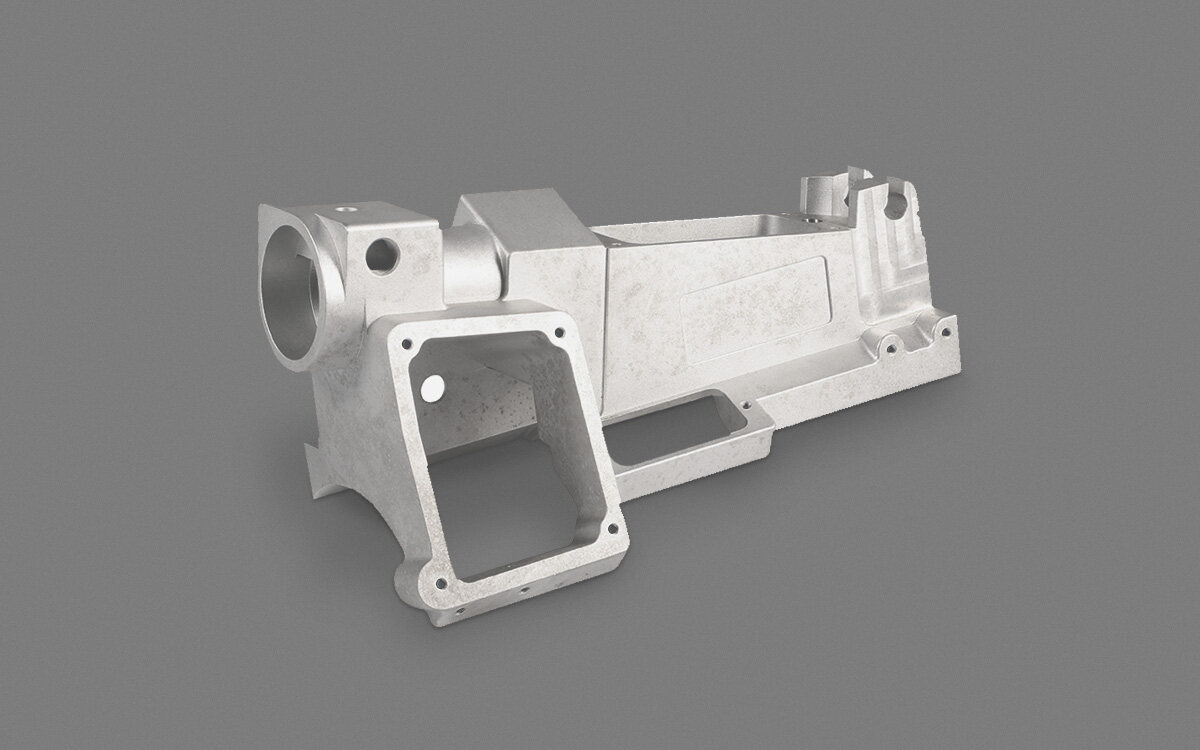

Q&A about Die Casting Part and Gravity Casting Part

Q: What is the difference between the aluminum die casting surface and the gravity casting surface?

A: whether it is die casting or low-pressure casting, gravity casting parts, or another casting (such as EPC), they all belong to the category of casting, but the casting process is different.

As far as alloys are concerned, alloys of different brands are similar except for their different compositions. Due to the strong affinity between aluminum and iron, the content of Fe in the die-casting aluminum alloy is mostly high, which solves the problem of welding adhesion between aluminum alloy and the die surface. In low-pressure casting and metal mold gravity casting, because the mold surface is coated with a special coating, the aluminum alloy liquid does not directly contact with the mold, so the content of Fe can be lower.

However, with the development of die-casting technology and the improvement of the performance of the die-casting machines, and the performance of die-casting release agents, pure aluminum die-casting is not a problem. Therefore, different alloy grades are only more suitable for a certain casting process, and there is no saying that only a certain casting process can be used.

Q: Which is more expensive, aluminum die casting or aluminum gravity casting?

A: This also depends on specific products. Generally speaking, for products with high density and airtightness requirements, especially those requiring post-processing, gravity casting has advantages, but some ordinary die castings have advantages. On the whole, gravity casting costs are high.

Q: Which is better, manual die casting or manual gravity casting?

A: When the temperature of the fire exceeds 200 ℃, the cast iron pot will control the temperature transmitted to the food at 230 ℃ by emitting certain heat energy; The refined iron pot directly transmits the temperature of the fire to the food.

For ordinary families, it is better to use a cast-iron pot. Because the cast iron pot is made of refined iron with fewer impurities, the heat transfer is relatively uniform and it is not easy to stick to the pot; Due to good materials, the temperature in the pot can reach higher; It has a high grade, smooth surface, and easy cleaning.

Compared with the ordinary so-called smokeless pot and nonstick pot, its unique uncoated design of pot body fundamentally eliminates the harm of chemical coating and aluminum products to the human body and enables the whole family to enjoy health and delicacy without damaging the nutritional components of dishes.

Q: As far as aluminum castings are concerned, which is better in terms of performance and appearance between products produced by gravity casting (metal mold casting) and products produced by die casting?

A: Generally, the appearance of die-casting will be smooth and bright, because the filling time is short and there are few cold lines on the surface. However, if the die-casting can not meet the product requirements, it must also be cast by gravity. Generally, surface treatment is required, such as shot blasting and grinding. The performance of die casting is better, with high strength and strong torque. Gravity casting is suitable for large castings, such as cylinder blocks.

We are the leading and professional OEM aluminum die casting parts, if you are interested in gravity die casting parts, welcome to contact us at any time, we also supply Precision Casting Parts!