Email tɛ se ka kɛ lankolon ye

Password tɛ se ka kɛ lankolon ye

Email cogoya fili

Email tɛ se ka kɛ lankolon ye

Email bɛ yen kaban

6-20 sɛbɛnni(sɛbɛnniw fara jatedenw dɔrɔn kan)

Daɲɛ dogolen tɛ bɛn ɲɔgɔn ma

Email cogoya fili

Email tɛ se ka kɛ lankolon ye

Email tɛ yen

6-20 sɛbɛnni(sɛbɛnniw fara jatedenw dɔrɔn kan)

Daɲɛ dogolen tɛ bɛn ɲɔgɔn ma

Kunnafoniw

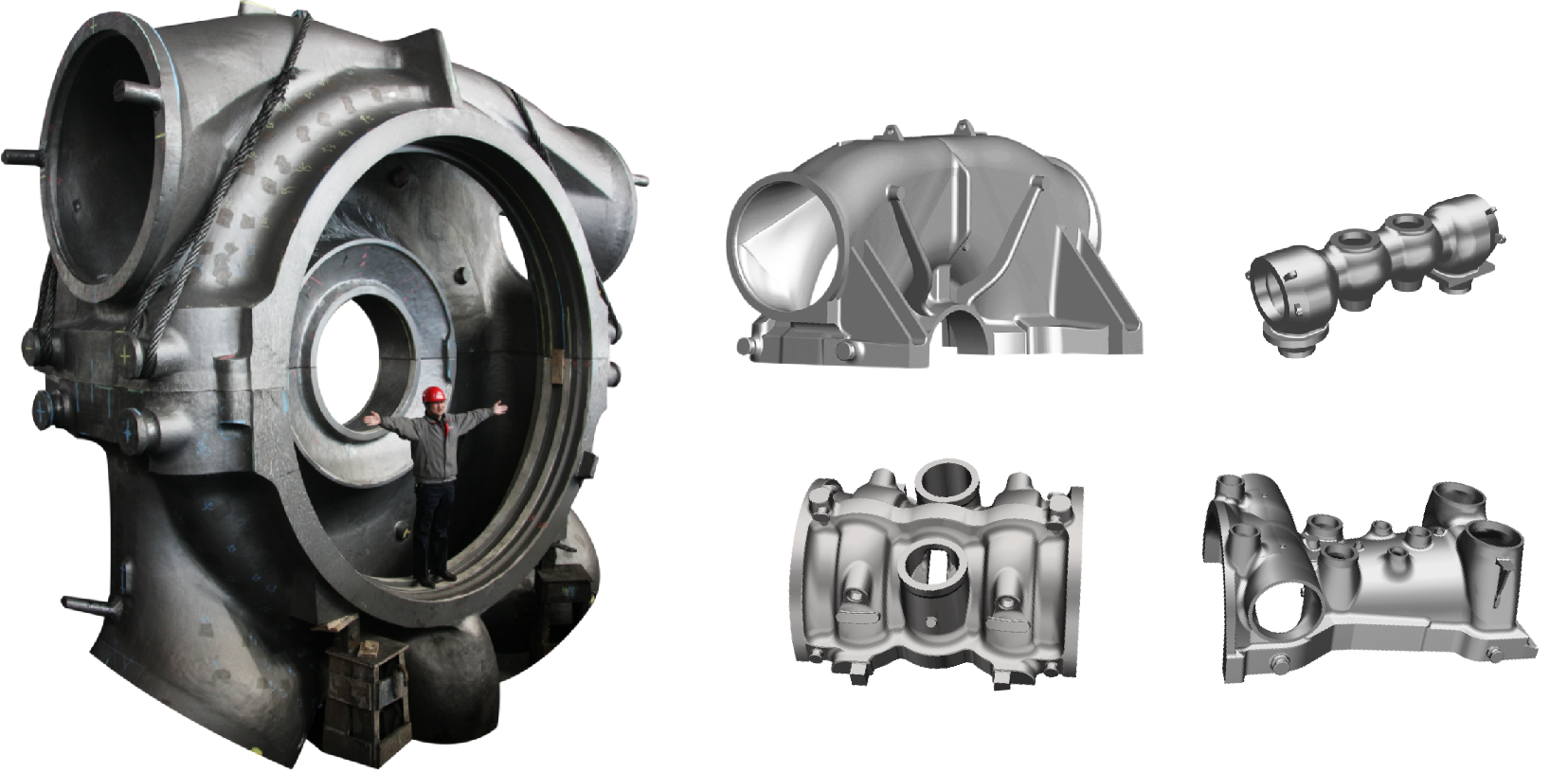

Process Methods and Advantages and Disadvantages of Ordinary Sand Casting

Sand casting is a sand casting process used to manufacture large components such as gray cast iron, ductile iron, stainless steel, and other types of steel. The main steps include painting, molding, core making, molding, melting and pouring, cleaning, etc.

The basic raw materials of ordinary sand casting are foundry sand and sand binder. The outer sand mold used in sand casting is divided into three types: clay wet sand mold, clay dry sand mold, and chemical hardened sand mold according to the binder used in the molding sand and the way of building its strength.

Selection of process parameters

- Machining allowance

The so-called machining allowance is the surface that needs to be cut on the casting. A certain machining allowance should be reserved in advance, and its size depends on many factors such as the type of casting alloy, the molding method, the size of the casting, and the position of the machined surface in the casting mold.

- The draft angle

In order to make the pattern easy to take out from the mold, the slope added to the vertical wall perpendicular to the parting surface is called the draft slope.

- Casting fillet

In order to prevent the casting from producing stress and cracks at the connection and corner of the wall, and to prevent the sharp corners of the mold from being damaged and producing blisters, when designing the casting, the connection and corner parts of the casting wall should be designed with rounded corners.

- Core head

In order to ensure the positioning, fixation, and exhaust of the core in the mold, the core head should be designed for both the pattern and the core.

- Shrinkage margin

Due to the cooling shrinkage of the casting after pouring, this part of the shrinkage dimension should be added when making the pattern.

Advantage

- Clay is rich in resources and cheap. Most of the used clay wet sand can be recycled and reused after proper sand treatment;

- The cycle of making the mold is short and the work efficiency is high;

- The mixed molding sand can be used for a long time;

- Wide adaptability. Small pieces, large pieces, simple pieces, complex pieces, single pieces, and large batches can be used;

Disadvantages and limitations

- Because each sand casting mold can only be poured once, the casting mold is damaged after the casting is obtained and must be reshaped, so the production efficiency of sand casting is low;

- The rigidity of the mold of the molding machine is not high, and the dimensional accuracy of the casting is poor;

- Castings are prone to defects such as sand flushing, sand inclusion, and pores.