Email tɛ se ka kɛ lankolon ye

Password tɛ se ka kɛ lankolon ye

Email cogoya fili

Email tɛ se ka kɛ lankolon ye

Email bɛ yen kaban

6-20 sɛbɛnni(sɛbɛnniw fara jatedenw dɔrɔn kan)

Daɲɛ dogolen tɛ bɛn ɲɔgɔn ma

Email cogoya fili

Email tɛ se ka kɛ lankolon ye

Email tɛ yen

6-20 sɛbɛnni(sɛbɛnniw fara jatedenw dɔrɔn kan)

Daɲɛ dogolen tɛ bɛn ɲɔgɔn ma

Kunnafoniw

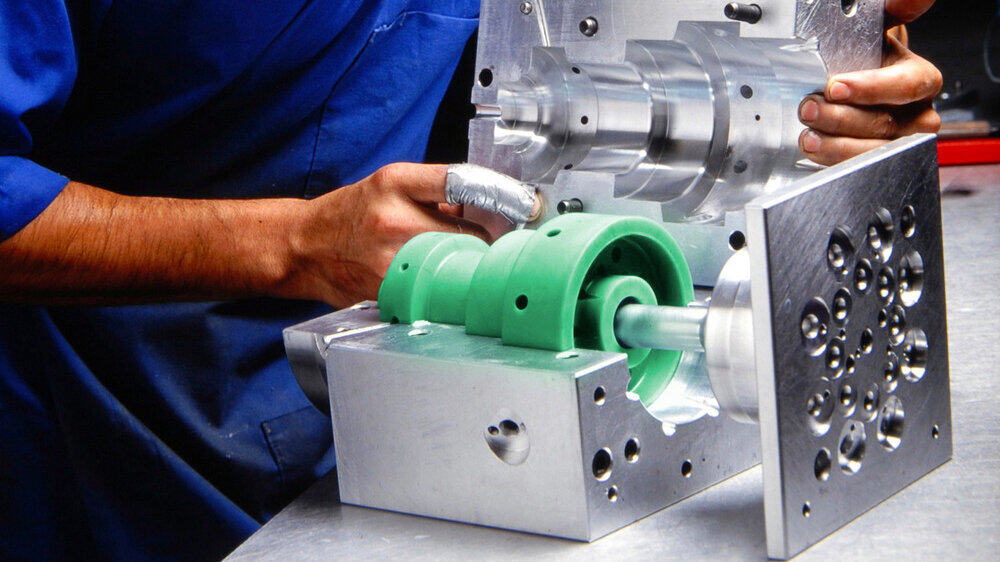

Features of 3-Axis, 4-Axis And 5-Axis CNC Machines

Most CNC mills can use 3 to 5 axis - typically providing performance along the XYZ axis and (if applicable) around the rotational axis. The X and Y axis represent horizontal movement (moving left and right and back and forth on the plane, respectively), while the Z axis represents vertical movement (moving up and down), and W represents horizontal movement. - The axis represents the diagonal movement in the vertical plane. In basic CNC milling machines, horizontal movement is possible in two axis (XY), while newer models allow additional axis of motion, such as 3-, 4-, and 5-axis CNC machines. Below is an overview of some of the characteristics of milling machines classified by the number of axis of motion.

Features of 3-axis, 4-axis and 5-axis CNC machines

3 axis

- Able to meet most machining needs

- Easy machine setup.

- Only one workstation is required

- Higher knowledge requirements for operators

- Lower efficiency and quality

4 axis

- Better capabilities than 3-axis machines

- Higher precision and accuracy than 3-axis machines

- Machine setup is more complex than 3-axis machines

- More expensive than 3-axis machines

5 axis

- Can be configured with multiple axis(e.g. 4+1, 3+2 or 5)

- More powerful

- According to the configuration, it is more convenient to operate than the three-axis and four-axis machine tools.

- Higher levels of quality and precision

- Depending on configuration, it runs slower than 3-axis and 4-axis machining

- More expensive than 3-axis and 4-axis machines

Depending on the type of milling machine used, the machine, the machine table or both components can be dynamic. Typically, dynamic tables move along the XY axis, but they can also move up and down to adjust the depth of cut, and rotate along the vertical or horizontal axis to expand the cut. For milling applications requiring dynamic tools, in addition to its inherent rotational motion, the machine tool moves vertically along multiple axis, allowing the circumference of the tool (rather than just its tip) to cut into the workpiece. CNC milling machines with greater degrees of freedom allow for greater versatility and complexity of the milled parts produced.

Features of CNC Milling

CNC milling is a machining process suitable for machining a variety of materials and producing a variety of custom-designed parts. While this process may show advantages over other machining processes, it may not be suitable for every manufacturing application, and other processes may prove more suitable and cost-effective.

Some other more conventional machining processes include drilling and turning. Like milling, drilling is usually done with a multi-point tool (i.e. a drill), while turning is done with a single-point tool. However, while rotating, the workpiece can move and rotate like some milling applications, while during drilling, the workpiece is stationary throughout the drilling process.

Some unconventional machining processes (i.e., without the use of machine tools, but still with mechanical material removal processes) include ultrasonic machining, water jet cutting, and abrasive jet machining. Unconventional, non-machining processes (i.e. chemical, electrical, and thermal machining processes) provide other alternatives to removing material from workpieces that do not use machine tools or mechanical material removal processes, including chemical milling, electrochemical deburring, laser Cutting and plasma arc cutting. These unconventional machining methods support the production of more complex, more demanding and specialized parts that are often not possible with conventional machining.

Conclusion

For more information about victor cnc milling machine,hobby cnc milling machine for sale,cnc milling engraving machine, we are glad to answer for you.